Spur vs Helical Rack is a vital part of understanding CNC motion control systems. When you’re researching CNC machines, one of the key mechanical details you’ll encounter is the rack and pinion drive system. This system converts the rotary motion of a motor into the linear motion needed to move a CNC gantry or cutting head. Two of the most common types are spur rack and pinion and helical rack and pinion. Both can deliver reliable motion, but each has advantages and trade-offs.

In this article, we’ll break down the differences so you can make an informed decision when choosing or upgrading a CNC machine.

What Is a Rack and Pinion Drive?

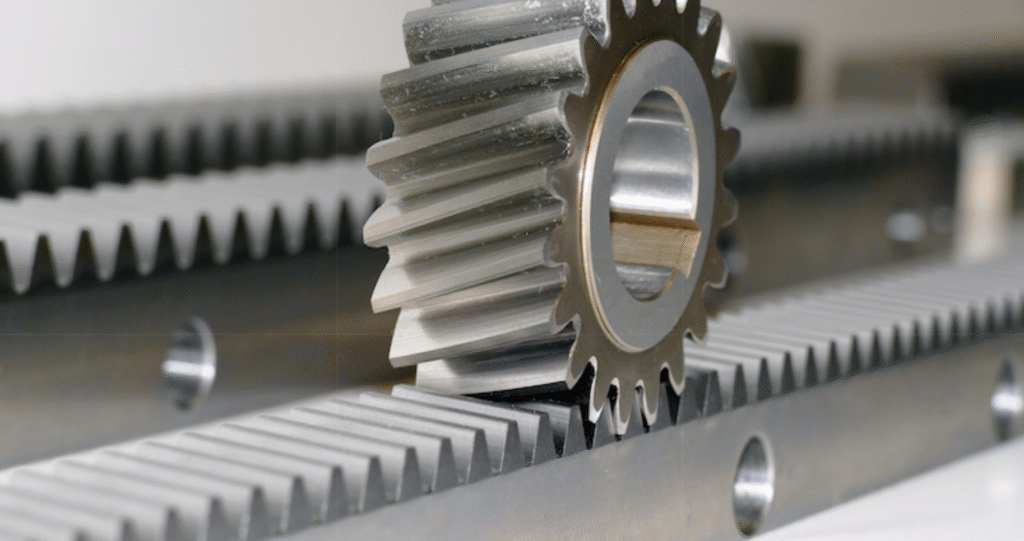

A rack and pinion consists of two parts:

- Rack: a straight gear mounted to the machine bed.

- Pinion: a round gear attached to the motor shaft.

As the pinion rotates, it moves along the rack’s teeth, driving the CNC axis in a straight line. This design is popular on larger CNC routers and machines because it can deliver long travel distances without the stretch or cost issues of ball screws.

Spur Rack and Pinion

Spur gears have straight teeth that are cut parallel to the pinion’s axis. They are the simplest and most widely used gear design.

Benefits of Spur Rack and Pinion:

- Cost-effective: Easier to manufacture, so machines with spur drives are generally more affordable.

- High efficiency: Less sliding friction means minimal energy loss.

- Easy to maintain: Straightforward design makes replacement and alignment simpler.

Drawbacks of Spur Rack and Pinion:

- Noise: Straight teeth engage all at once, creating more vibration and gear noise at higher speeds.

- Backlash: Slight gaps between teeth can introduce play, reducing accuracy in very detailed CNC work.

- Wear: The impact of tooth-to-tooth contact can increase wear over time in heavy-duty or high-speed use.

Helical Rack and Pinion

Helical gears have teeth cut at an angle, which allows for smoother and more gradual engagement compared to spur gears.

Benefits of Helical Rack and Pinion:

- Smooth operation: Angled teeth mesh gradually, reducing vibration and chatter.

- Higher accuracy: Less backlash means improved precision, especially important for detailed carvings, sign work, and 3D machining.

- Durability: Load is spread across multiple teeth, which reduces localized wear.

- Quieter running: Noticeably less gear noise, even at high feed rates.

Drawbacks of Helical Rack and Pinion:

- Higher cost: More complex to manufacture, making these drives more expensive.

- Slight efficiency loss: Angled teeth introduce some sliding friction, requiring slightly more motor torque.

- Alignment sensitivity: Proper setup is critical; misalignment can increase wear.

Spur vs helical Rack, Which Is Best for CNC Machines?

- For hobbyists or budget-minded shops: Spur rack and pinion systems provide reliable motion at a lower price point. They’re a great fit for general woodworking, cabinetry, and projects where ultra-high precision isn’t required.

- For professional shops or high-accuracy work: Helical rack and pinion systems are worth the investment. They deliver smoother motion, better cut quality, and quieter operation — all critical when running a CNC machine all day.

Spur vs helical Rack, Conclusion

Comparing Spur vs helical rack will help you understand your machine or a machine you might purchase. Both spur and helical rack and pinion drive systems are proven technologies in CNC motion control. Spur gears are simple, affordable, and effective, while helical gears provide smoother, quieter, and more precise performance at a higher cost. The right choice depends on your budget, application, and how much you value long-term accuracy and operator comfort.

If you’re considering CNC training or looking to understand machine design before buying your first router, the North Carolina Furniture School offers hands-on classes in CAD/CAM and CNC machining. Our goal is to help makers gain the confidence to use these technologies effectively. If you would like to learn more about Spur vs helical rack CNC drive systems, and other aspects of the CNC machine, we invite you to sign up for a CNC class today!

👉 Explore our CNC classes here: NC Furniture School – CNC Training